Techflow Enterprises Pvt Ltd is remarkably reliable and one of the capital suppliers of Air Pollution Control products like Pulse Jet Bag Filters, De-Dusting System, Pulse Jet Dust Collector, Dust collector for Dryers, Dust Recovery System, Dust collector for sander, Air Pollution Control Equipments, Furnace Fume Extraction System, Bag House, Online Cleaning Bag Filter, Offline Cleaning Bag Filter, and Reverse Air Cleaned Bag Filter, Fabric Filter, Silo Vent Filter, Bag Filter for boiler, Flue Gas Emission Control System, Welding Fume Extraction System, Centrifugal Fans & Blowers, Pneumatic Conveying System, Cassette Type Filter, Electrostatic Precipitator, and ESP To the diverse parts of industries nationally and in foreign countries all over the world.

Techflow Enterprises Pvt Ltd has been dealing out mandatory machines to various industry segments like Air Pollution Control Systems, Boilers Flue Gas, Mining and Minerals, Coal Handling, Cement, Particle Board Manufacturing, Kiln Exhaust, Glass, Foundry & Steel, Solid Drying, Hot Gases and Fumes, Wood-Working & Laminates, and loads more industries.

Discover more| Dust collector for Dryers |

|---|

Dust collector for Dryers is normally used to generate steam for Power Plants, Sugar Mills, Process Houses, Chemical Plants, and many others. |

To invent steam, these Dust collectors for dryers use Energies that are reusable like LPG, Electricity, Gas, Oil, and Solid Fuels. Out of the detailed fuels, solid fuels are the less expensive and the majorly used resources despite they are most polluting. Aspiring to control this emission of solid fuel, TECHNOFLOW plants, and supplies a very efficient pollution control system. These systems are known as many familiar terms throughout the world, such as bag filter for boiler, ESP for boiler, Pulse jet bag filter, De-dusting system, Baghouse, and Bag Filter. Pollution control equipment or bag filters for Dust collector are obtainable in many formations to maintain gush from various sorts of solid fuels like-Bag Filter for bagasse fired, Bag filters for wood-fired boilers, waste incineration boilers for waste to energy plants, Bag Filter for food and agriculture waste fired boilers, and Bag filters for Coal-fired boilers. We at TECHFLOW supply all of them with dignity as per the requirement. |

Techflow is Ahmedabad, Gujarat-based responsible manufacturer, and supplier of air pollution control systems like Bag Filter. With carriers all over the globe, Techflow has a consumer-oriented design and furnishes the most optimistic solution for preventing air pollution in industries has made it a trustworthy associate partner for many elements of the industry. Set it up as a preferred partner for delivering according to their demands for the most fitting quality bag filter. |

The air pollution control systems for boilers are usually supplied a majority of the time to the plants like- Dairy, Power Plants, Chemical Plants, Process Houses, Cement Plants, Steel Plants, Sugar Mills, Pharmaceuticals, and Paper. |

TECHFLOW Structures and supplies Pollution Control System and Pulse Jet Bag Filter for boilers On the Bases of fuel and demand of vent emission. Defined here are the two prior types of TECHFLOW-used pulse jet bag filters to control pollution from the boiler. |

1. Online Cleaned Dust collector for Dryers

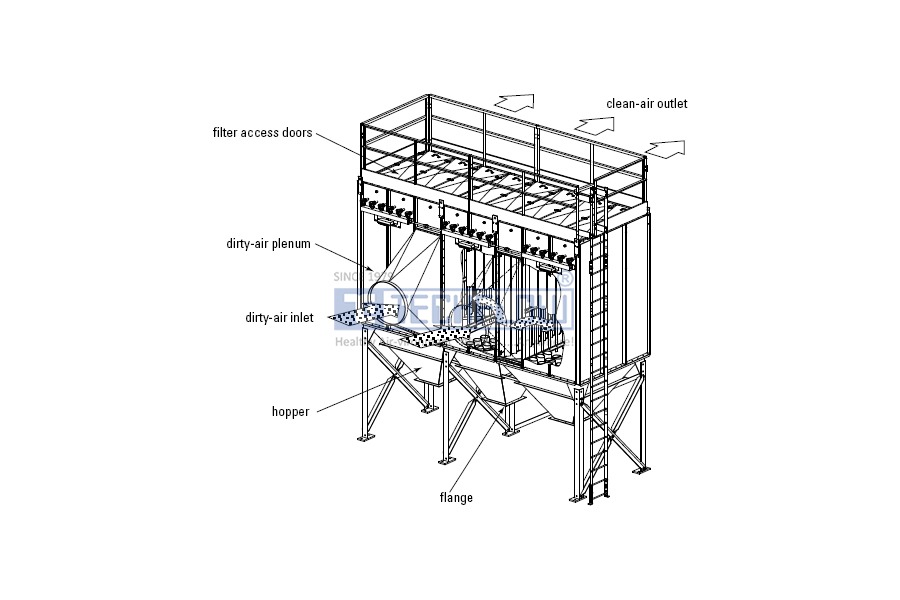

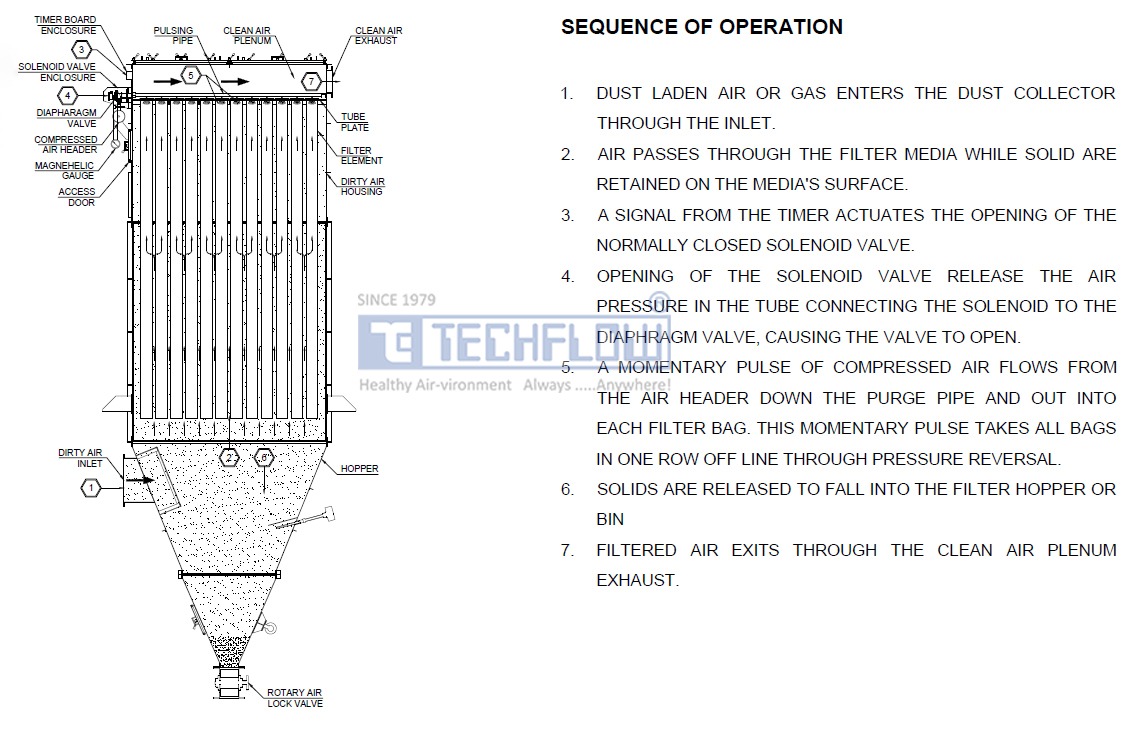

Where the big and heavy particulates go down from the air stream, the air full of dust gets into the hopper. The light particles are grabbed in the air and then go up to the filter bags. As the air goes through the filter bags, the dust particles are fetched together on the filter bag's external side, and the cleansed air gets depleted thru the collector. At even intervals, the jets of compressed high-pressure air passed through the venturis through blowpipes and pulse. It involves a brief reversing robust flow of secondary air thru the bags. This causes the production of an inner shock wave that makes the bag pressurize and band outer as the shock reaches down to the length of a bag. The process expels the dust of the inverted airflow on the exterior of the bag which then settles down into a collector called a hopper. Through this procedure, airflow is switched for a fraction of a second via a row of bags. Over the dust collector, this then results in a continued airflow state. The Cleaning Operation is smoothly controlled and modified with a Solid State timer. The differential force gauge permits and maintains optimal regulation of the timer. To reduce the compressed air utilization in the process, the pulse gaps and spans can be properly and simply altered at the timer.

2. Off line Cleaned Dust collector for Dryers

Sorting of Pulse-Jet baghouses is also possible. In this case, the gush of the dirty air into the segments is stopped by the Isolation/Poppet valves placed in the pure air plenum. There is a chance to equip each of the parts with either a one pulse valve that gives the cluster of bags with compressed air or have the direct pulsing air blown into the blowpipes that are above the bag rows in the components via individual pulsing valves. The airflow all over the segment is prevented while the cleaning cycle as the isolation damper closes. For this procedure of cleaning, an explosion of air is filled into the bags via the start of the pulse valve for approx 0.2 sec. while the procedure of pulsing, the segment stays offline. The time for that, despite, can be longer or shorter as per request. The segment is brought back on stream upon the automatic reopening of the Isolation/Poppet. Via this method of Off-line Cleaning, until and unless every bag in the baghouse has been cleansed, the alternate segments are sequentially cleaned. While the baghouse constantly gains very low emission levels, It permits very extensive bag cleansing as it is oftentimes used on fabric filters installed on low size density product/dust.